×

Welcome to NZ Engineering Works. NZEW established in 2007, Located in Kanpur, Uttar Pradesh, India by Mr. M. Nasir (Founder) under his lead & guidance company completed his target every year. We are a dynamic mechanical engineering company that strives to provide superior customer service to our commercial and industrial clients in across India. Our boilermakers, pipefitters, and welders can professionally install and maintain all components of your heating system.

We focused on the Paper, Sugar, Chemical Refinery, Edibles & Dairy Industry, We experience and qualifications quickly progressed into other industries, including Oil & Gas, Petrochemical, Thermal, Food Processing & Pharmaceutical Industries.

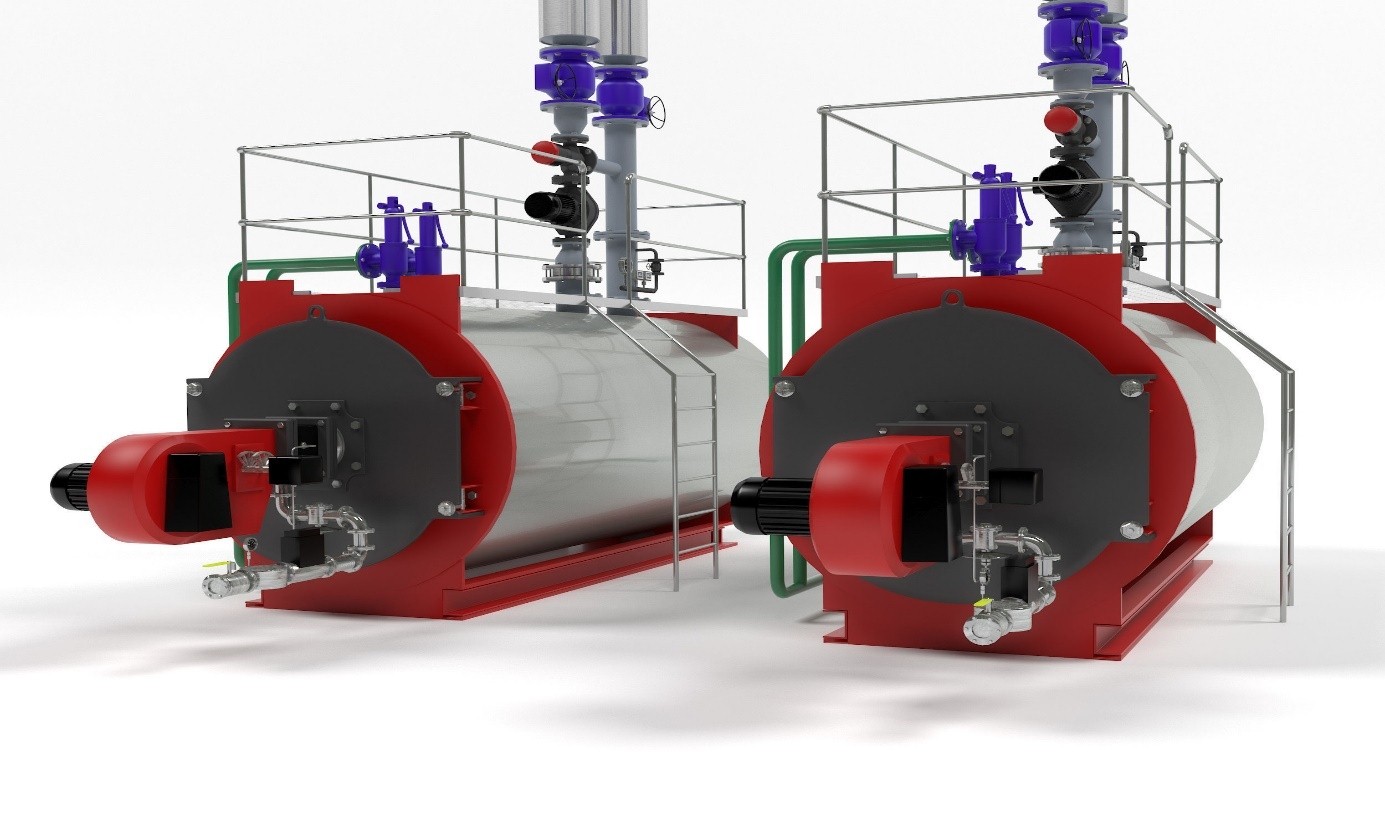

Now, NZEW has grown into different distinct business unit Manufacturing, Operation & Boiler Maintenance. Supplying and Installing the all types of industrial boilers Together, we offer a full range of world-class services and capabilities, from accurate manufacturing and Fabrication. As the main export base of industrial boilers and power plant boilers in across India, We established a sterling reputation in the industry and look to improve it with every job.

Combining technical and operational expertise, single-source capabilities and proven processes, NZEW achieved more than 170 clients satisfaction every year and constantly we achieving it. NZEW helps our clients achieve superior operational safety, reliability, and cost efficiency. With our experienced team of engineers and highly trained technicians, we meet our client’s operational challenges with confidence and trust.

NZEW maximizes the efficiency and lifespan of your industrial boiler and recovery systems.

NZEW has the experience and expertise to install, maintenance or service your industrial boiler system. NZEW employs a dedicated preplanning process to identify optimal construction procedures and modularization opportunities.

PULP & PAPER INDUSTRY BOILER The most experienced Pulp & Paper team in the industry - Increase the lifespan and efficiency of your boiler and recovery system.

Pulp and Paper Industry Boiler Systems Extending the life of your pulp & paper process boilers and recovery systems. Pulp & Paper Mill boilers and recovery systems are designed to utilize waste by-products to fuel their power needs. These systems often rely on biomass fuel sources, such as black liquor, organic waste material, or coal. These materials can release large amounts of corrosive and erosive exhaust gases that could prematurely shorten equipment life.

Types of Pulp and Paper Boilers With more than 25 years of experience in the pulp & paper industry, NZEW has the expertise to maximize the lifespan of your boiler system. We specialize in modernizing pulp and paper boiler systems to meet changing government regulations, such as the Boiler ACT rule.

Recovery Boilers Many pulp & paper recovery boilers are nearing the end of their 30-year lifecycle and will require plant shutdown if not properly serviced or maintained. NZEW can help you upgrade to a new high-efficiency recovery boiler.

POWER PLANT INDUSTRY BOILER Meeting your toughest outage deadlines - Expert service and rapid response without compromising safety and quality.

Rapid response for the power generation industry. NZEW has the experience to meet the power generation industry’s quick response needs. We offer services for boiler room repairs, process changes, maintenance and new investments. Our services are focused on the manufacture and installation of boiler structures and components, often including detailed structural engineering.

Our strengths in repair and maintenance include quick service, site-specific solutions and highly competent installation crews. We have sufficient resources for all situations and extensive projects as we are able to utilise our skilled labour force in our other units. We have decades-long experience in the maintenance of power plant boilers.

Quick deliveries enable our clients to minimise shutdown periods. In addition to our expertise, we have the right attitude. We are ready to provide service around the clock.

CHEMICAL & REFINERY INDUSTRY BOILER Maintaining operating efficiency - We aim to reduce emissions, improve feed water quality, and prevent contamination.

Ensuring overall system reliability for the Chemical & Refinery Industry. NZEW understands the extreme conditions of Chemical & Refinery boiler systems and how they can impact plant operations.

Chemical & Refinery boiler types are subjected to constantly changing conditions and are at high risk for boiler corrosion, tube scale, fouling, and/or failure of critical equipment such as economizers and turbines. Our chemical cleaning process can remove residual deposits of rust and mill-scale that can hinder flow and circulation.

All Refinery & Chemical boiler servicing projects include an extensive constructability and preplanning phase to identify opportunities for cost and labor reductions. Our extensive planning has been proven to improve overall efficiency and ensure long-term, reliable boiler performance.

Gas-Fired Boilers NZEW specializes in servicing gas-fired boilers for the Chemical & Refinery industry, including power and process piping, burner replacements, and environmental/air systems to ensure efficient delivery of process steam.

DAIRY INDUSTRY BOILER Dairy Industrial Boilers are mostly used in dairy industry for milk pasteurization and UHT. Milk Product has high quality and high sanitary needs and very important.

Dairy plants process the raw milk they receive from farmers so as to extend its marketable life. Two main types of processes are employed: heat treatment to ensure the safety of milk for human consumption and to lengthen its shelf-life, and dehydrating dairy products such as butter, hard cheese and milk powders so that they can be stored.

Dairy Industrial Boilers are mostly used in dairy industry for milk pasteurization and UHT. Milk Product has high quality and high sanitary needs and very important.

Milk Boiler ensures good shelf life and destroys disease-causing microorganisms. This emphasizes the requirement for flexible and reliable heat sources, which may keep the dairy milk systems running without any hurdle.

DISTILLERY INDUSTRY BOILER We supply types of boilers for the generation of steam and power required for the operation of sugar mill.

Electricity and steam are almost required in every step of raw sugar process, especially in juice extraction, clarification, evaporation and sugar drying, good quality steam takes a crucial role. Thus selection of steam boilers becomes very important for sugar plant. Bagasse, nearly 30% fiber contained in sugar cane, is produced during the processing of sugarcane, is burned as fuel for the generation of steam and power required for the operation of sugar mill. In fact, most cane sugar factories have been designed to be energy self-sufficient, with sugar as the primary product and bagasse as the primary fuel.

A bagasse-fired cogeneration system, made of steam boilers and steam driven turbo-alternators, provides all the steam and electricity needed to run the cane mills and factory, leaving little surplus bagasse. The bagasse is fired in the boiler for producing steam at high pressure, which is extracted through various single high capacity turbines and used in the process.

NZEW specializes in servicing and installing industrial boiler types for multiple applications.

With more than 36 years of experience servicing and installing industrial boilers and essential equipment, NZ Engineering Works is the boiler shutdown contractor of choice for multiple industries. From coal and recovery boilers to bark and biomass, NZEW offers specialized knowledge and innovative solutions for most types of industrial boilers.

COAL BOILERS When a quick response is critical - We know the unique maintenance requirements and challenges associated with coal boilers.

NZEW ensures your coal boiler operates at the highest levels of efficiency. Coal boilers are commonly used to heat water and create steam for energy production. Coal-fired boiler efficiency can often provide lower operating costs in comparison to other fossil fuels – almost 75% less than oil or natural gas. Coal, when properly handled and combusted, is one of the cleanest fossil fuels available today.

NZEW offers expert field services, including repair, fabrication, and installations to help operate and maintain your coal boiler at the highest efficiency levels possible.

Coal Boiler Capabilities and Systems Serviced We understand that a quick response is critical when process and power applications are at stake. Our crew of safety-conscious and highly-trained employees - including code certified and skilled welders - is available to get your coal boiler back online with minimal down time. NZEW also provides essential component upgrades and field services for coal boilers, including:

GAS BOILERS Ensuring efficient power production - NZEW services common gas boiler problems for quick and efficient heating.

NZEW services common gas boiler problems, ensuring quick and efficient heating for multiple applications. Industrial gas boilers are primarily used for heating water for the creation of process steam. Plants commonly use natural gas boilers to produce power for multiple applications.

A distinct advantage of the industrial gas boilers is the availability of natural gas resources and its high energy-to-heat ratio. NZ Engineering Works specializes in servicing common industrial gas boiler problems, as well as installing replacement gas boilers to maintain high efficiencies.

Gas Boilers - Capabilities and Systems Serviced With a highly-skilled and dedicated workforce of employees in our database, National Boiler is prepared to meet your gas boiler installation, maintenance, or repair needs. Contact us when erecting a new boiler or repairing/retrofitting an existing industrial gas-fired boiler for expert consultation. We also offer component upgrades and field services, including:

RECOVERY BOILERS We know the heart of Pulp & Paper - Upgrade your recovery boiler to meet emission standards and increase efficiency.

NZEW specializes in servicing the heart of the pulp and paper industry. Recovery boilers were first invented in the early 1930s and have since been a key player in the Kraft process of pulping

While replacement of recovery boilers does not usually happen until the end of their economic lifetime (a lifespan that can average up to 40 years), upgrading your recovery boiler system to meet modern standards provides new opportunities to optimize energy savings and reduce emissions.

Recovery Boilers - Capabilities and Systems Serviced NZEW has Pulp & Paper teams devoted to servicing waste heat recovery boilers and related components. Our field services range from assistance in scheduling your next planned shutdown and boiler condition assessments to immediate response when emergency situations occur.

We provide installation of the latest technology and modularized components to increase the overall efficiency of your recovery boiler and reduce maintenance. We also offer essential component upgrades and field services for recovery boilers, including:

BARK BOILERS Optimize energy production and reduce cost - Preventive maintenance and periodic upgrades help maintain maximum efficiency.

Maintaining maximum efficiency for bark boilers and the Pulp & Paper industry. Bark boilers are primarily used in pulp and paper mills to produce process steam for paper production. These boilers are especially efficient in the production of pulp and paper, as bark is a waste by-product of previous processes involved in paper making. Steam is generated when the bark waste is burned and converted to process steam that turns a turbine to produce electrical power.

NZEW can help the Pulp & Paper industry optimize the production of energy from wood waste and reduce overall energy costs. NZEW can also help bark boilers maintain maximum efficiency through preventive maintenance and periodic upgrades.

Bark Boilers - Capabilities and Systems Serviced NZEW understands that most of the problems associated with bark boilers are related to inadequate mixing between the combustible gases and air. NZEW specializes in preventative maintenance and boiler optimization to safeguard against this and other common bark boiler problems. In addition to bark boiler installations and emergency repairs, NZEW also provides essential component upgrades and field services for bark boilers, including: